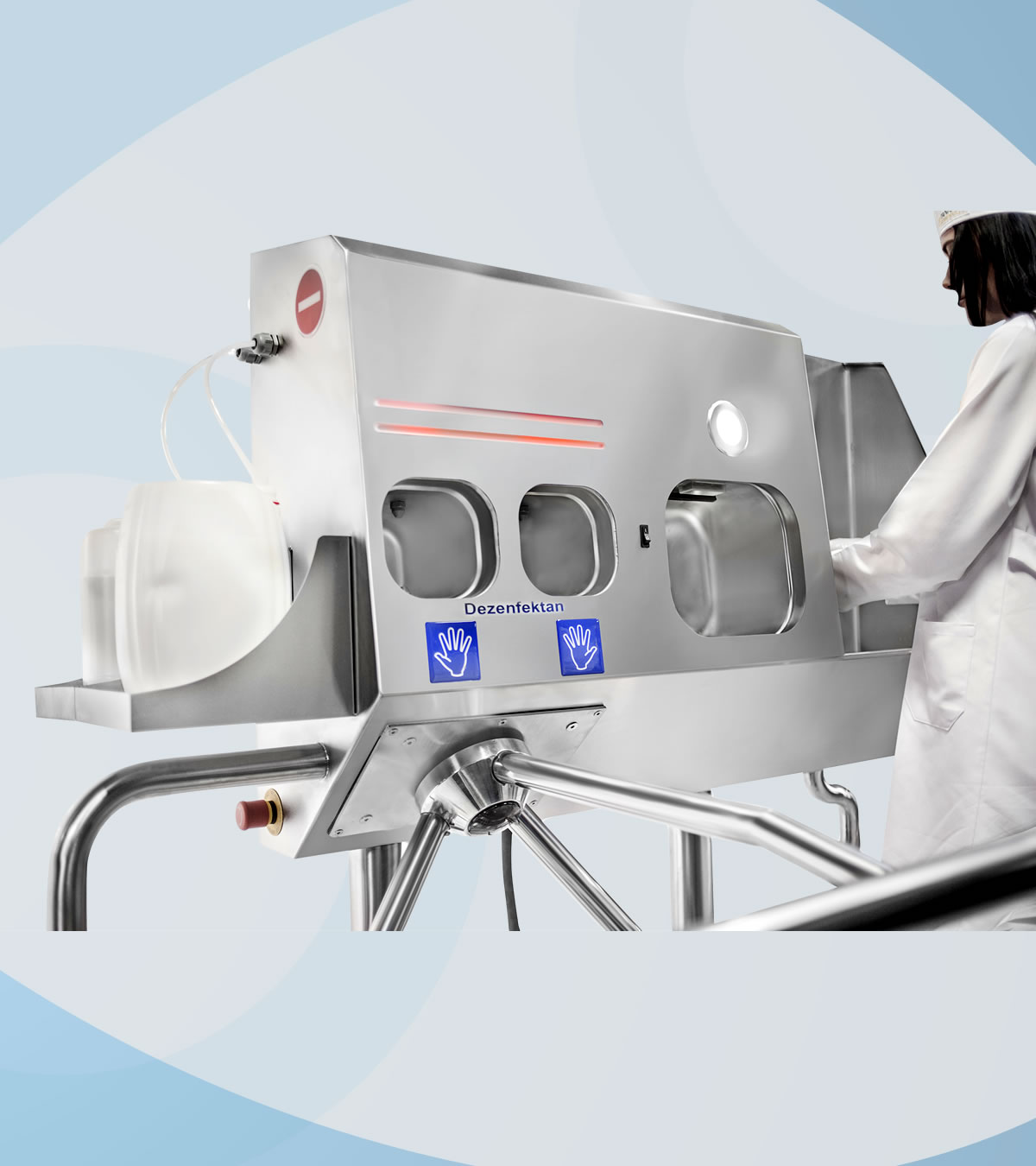

COMPACT-TAF Compact Hygiene Barrier with Sink, Jet Dryer, Hand and Sole Disinfectant

Our machine is designed as a comprehensive hygiene station that includes hand washing, hand drying and hand disinfectant turnstile and shoe sole cleaning system. The sink works with the sensor, and the hand disinfection station offers washing, drying and disinfection processes together via sensors without the need for any physical contact.

Product Request a Quote

Our machine is designed as a comprehensive hygiene station that includes hand washing, hand drying and hand disinfectant turnstile and shoe sole cleaning system. The sink works with the sensor, and the hand disinfection station offers washing, drying and disinfection processes together via sensors without the need for any physical contact.

Extremely useful, easy-to-maintain and cost-effective. TARIVER stainless steel hygiene barriers offer suitable solutions for businesses that want to comply with high hygiene standards.

What does COMPACT-TAF hygiene barrier do?

This hygiene barrier has the advantage of making sanitation mandatory by placing it in places where there are frequent passes, at the entrances and exits of the workshop, to ensure the 100% Hygiene environment.

In high-capacity production facilities, without allowing staff to waste time and wait in line; All sanitation steps are completed without physical contact with sole cleaning brushes, hand washing, hand disinfection and jet dryer. Thus, hygiene is maintained by ensuring maximum employee sterilization in optimum time.

COMPACT-TAF Working Method and Properties

Disinfectant is sprayed when hands are inserted into the disinfectant compartments in the hygiene barrier. Disinfectant is not sprayed and the turnstile is not opened without putting both hands into the device at the same time. Furthermore the disinfection device does not work if the personnel skipped the hands wash step. Liquid Soap is mixed with the running tap water for 3 seconds while the hands are washed, after 3 seconds rinse water automatically flows. In this way, hands must be washed with soap and then disinfected.

Shoes’ Sole are cleaned with a mixture of water and chemicals sprayed to 1000mm brushes, there is a 42mm drain pipe beneath the brushes that is discharging the waste water from the machine.

The compact hygiene station combines all the components needed for the personal hygiene of a person who is entering the production area.

Hand Disinfection

Thanks to the sensors, chemicals are not used in vain and there is no waste of time. After mandatory step of washing your hands with soap, you are required to mandatory disinfect your hands in the disinfection compartments. The turnstile is released only after all the mandatory hygiene steps are completed.

Product Benefits

- Hands are washed with 100% soap, therefore no soap-free passage takes place.

- Washing and disinfecting the hands as well as washing the soles of the shoes takes place in one combined system.

- It operates with sensor control, therefore hand washing, drying and disinfection processes are carried out without any contact by hands.

- Hands Dry step is presented with Jet Hand dryer.

- Brushes penetrating deep into shoe soles are at a minimum level of contraction and thorough cleaning is provided.

- A mandatory hand disinfection is provided simultaneously, and the spray time of the hand disinfectant can be programmed optionally.

- The turnstile lock that can be adjusted for the free exit according to preference.

- Turnstile released permit duration can be adjusted.

- Our product has a quality and hygienic surface structure thanks to satin stainless steel. Infection and contamination risk is minimized.

- Adjustable chemical dosage is possible. It offers washing, drying and disinfection processes together via sensors without any need for physical contact with the hands, eliminating the risk of contamination.

Machine Dimensions: 2150mm (length) x 1000mm (width) x 1950mm (height)

TANRIVER hygiene barriers guarantee personnel hygiene in a wide variety of industries, which are very important especially at production entry and exit points.

- Approximate dimensions 2150mm (length) x 1000mm (width) x 1950mm (height)

- 1.5mm and 4.0mm hair thickness

- 1000mm long horizontal base brushes

- 4 point disinfectant spray

- Emergency stop button

- The use of fresh solutions for footwear in every pass

- Adjustable stainless feet

- Two-hand mandatory disinfectant compartments

- There are alternatives with filling mat and upper body.

- Strong chassis, isolated welded, industrial design

- IP 65 protection class

- Hand drying at jet speed

- Non-slip fixed steps

- Instant drainage for dirty water

- Easy to install and remove brushes.

- Complete 304 quality stainless steel material

- Optional falling arm turnstile

- Automatic solution dosing and spraying to brushes

- Stainless steel 3 twist turnstile arm, special design.

- Stainless steel bars (balustrade)

- Automatic hand wash with soapy water

- PLC control system with Siemens logo

- One hundred percent hygiene requirement with trigger system

- Green and red led signal lights

- Timed spraying